In over 300 mines worldwide, Kinetic Mesh networks dynamically evolve to keep applications, equipment, and mine production running on the surface and underground, with no fiber or cell towers needed.

Rajant Kinetic Mesh® provides a mobile mining network that enables mining operators to meet continuous production and industry safety mandates with unwavering network availability. The unique nature of our Kinetic Mesh architecture allows open-pit and underground mines to easily introduce, relocate, or remove network infrastructure – without causing any network downtime – to deliver highly adaptable coverage and continuous connectivity. It is the only wireless mesh network for mining autonomy that runs without fail. Further, Rajant BreadCrumbs® provide 5x greater throughput, 5x lower latency, and 5x lower cost, compared to LTE

The world’s mines depend on Rajant for total mobility & autonomy: Kinetic Mesh networks are deployed throughout more than 300 of the largest open-pit and underground mines in over 80 countries today.

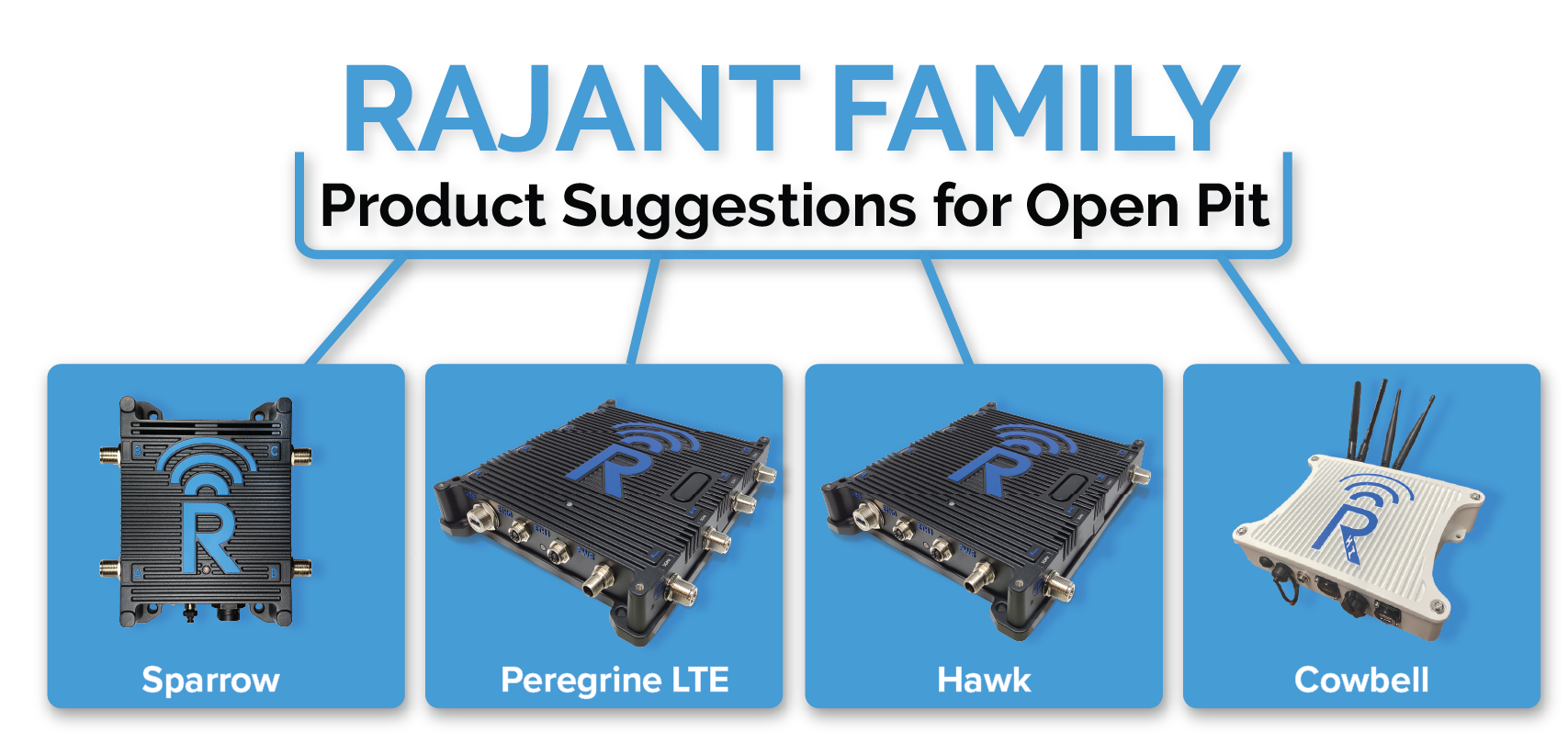

An Adaptable Network that Covers Ever-Changing Open-Pit Mines

The shape, depth, and configuration of a surface mine are constantly changing as extraction occurs. Equipment must be constantly moved away from new blast zones, which means network coverage must also frequently shift. Unlike large LTE towers, Kinetic Mesh’s unique and portable architecture easily allows open-pit operations to quickly introduce, relocate, or remove network infrastructure without operational downtime, to deliver highly adaptable coverage and continuous connectivity. Read our open-pit mining brochure to see how.

Click Here to Download Open-Pit Mining Brochure

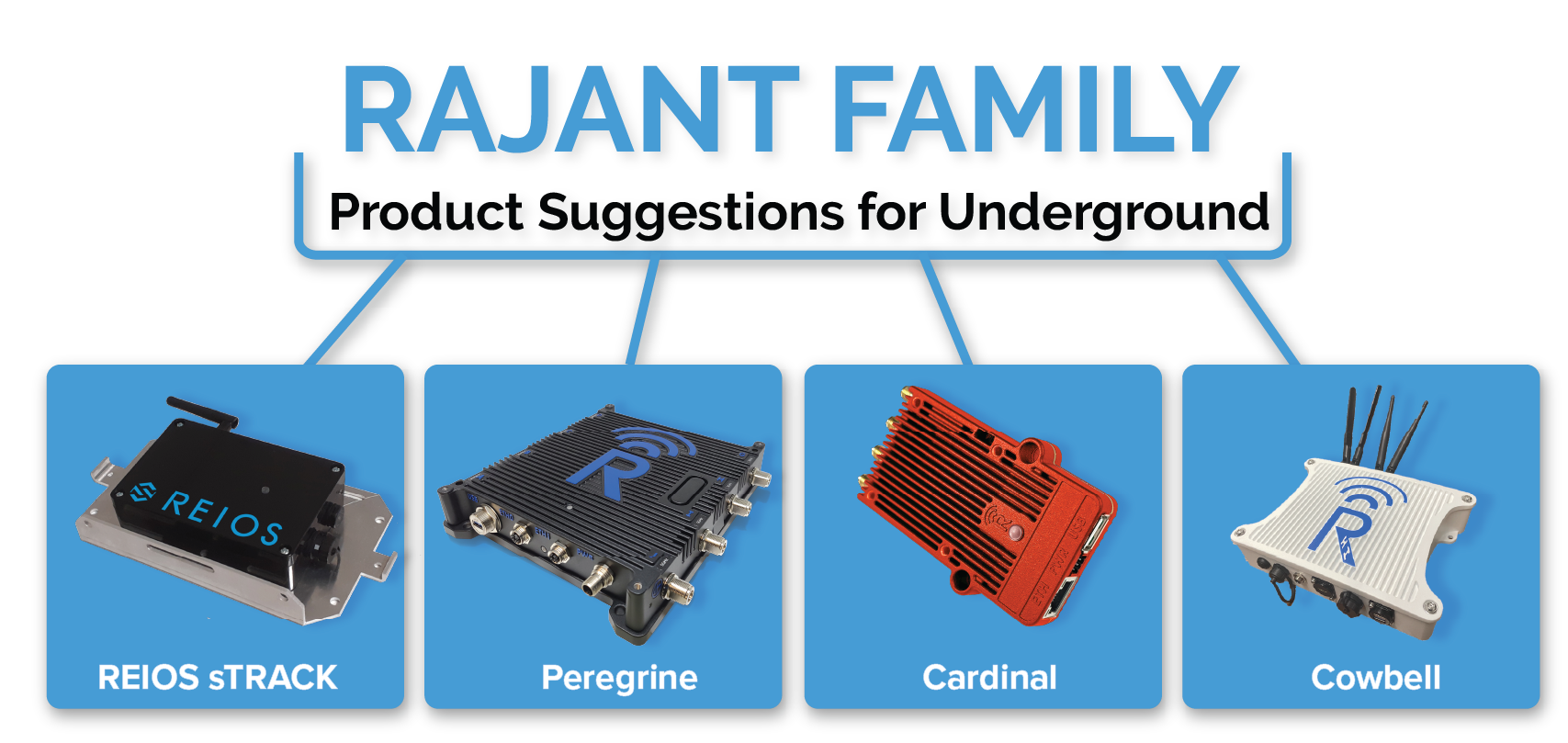

A Fully Mobile, Multi-Radio Wireless Mesh Network Underground

Underground mines are challenging environments in which to deploy network systems. Connectivity and throughput demands are high, but mine layouts limit how far wireless signals can travel. Rajant’s fully mobile, autonomous V2X/M2M for underground mining eliminates the struggles of a voice-only leaky feeder with multi-radio high-speed connectivity. Kinetic Mesh provides mission-critical voice and data communication at the working face for mines, which is a robust alternative to traditional wireless systems. Read our underground mining brochure to learn more.

Click Here to Download Underground Mining Brochure